The perfect miX for the packaging industry

Color plays such an important role in the packaging industry. But, which are the main color challenges for brand owners to meet customers´ expectations? And, how can they be faced?

Customer and brand owner surveys impressively show both

- why accurate colors play such an important role in the packaging industry and also

- which the main color challenges for brand owners are to meet customers´ expectations.

Even a quick look at some numbers highlight the power of color: Up to 85 % of customers´ first impression is based on color. The brand recognition is increased by color by up to 80 %. Only a little percentage is fine with color that differentiates from the image they have in mind. (1)

Color consistency = the key color challenge

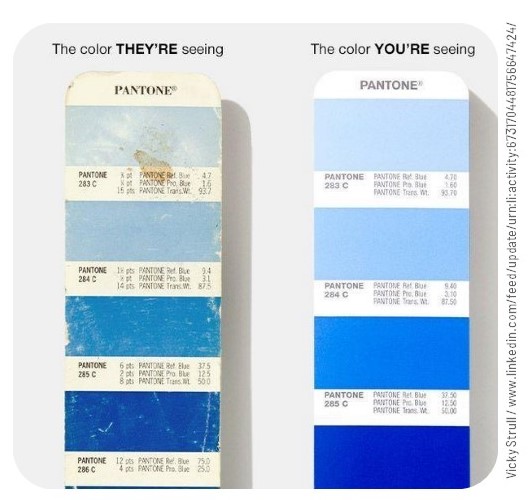

The key message is, that color consistency remains the main color challenge of brand owners, even for the real big global player. Decision-maker like Marc Hufschmied from PepsiCo concludes: “Consumers are very color sensitive, and have expectations around brand colors that need to be met consistently in a global marketplace “ (2).

Another brand owner points out the consequences if this is not considered: „Inconsistency puts doubts in the consumer´s mind and brings up concerns about the product inside“ (3).

New design trends even underline that, as minimalistic designs or widely used color gradients, strengthen the need for very accurate color reproduction.

Another important task for packaging companies is the efficient reproduction of color and the ability to shorten the time-to-market process of a product.

Brand owners agree, that nowadays packaging companies need to be agile and flexible in all steps of the supply chain like never before. There is no time for any detours, waiting times, or errors.

Manage the three P´s efficiently

Especially for packaging printers spot colors are essential due to several reasons, but working with them causes often lots of challenges:

- Process: Communicating spot colors is not that as easy as it may seem. As surveys show, many brand owner and their supply chain partner struggle with accurate color communication or need to handle inaccurate data which waste resources

- Proofing: Many companies still need to work with expensive or inaccurate packaging proofs and mock-ups which slow down the decision-making process and the market entry of new products

- Production: Production costs are high, packaging printers need to invest a lot of resources, waste time for a lot of ink changes, extended make-ready times, or need to deal with long delivery times – to mention just some implications of working with spot colors.

Suitable software solutions help to manage color easily and efficiently from artwork creation to delivery. Standardized processes can be established which build a strong basis to rely on – even in a crisis – and help to avoid errors.

Correct color communication is not just of great importance for large brand owners – it is important for anyone in this supply chain and will lead to benefits and profit for all of them.

Digital colors

One very crucial point is what we call the “true digitalization of color” as it is the fundament for successful color management today.

It does not only help to achieve consistent color management globally, but it also speeds up the time-to-market of a product, improves stock management as well as data collection and evaluation.

Clear objective numbers help to achieve the aim another brand owner expresses: „We want printing to go from an art to science and to rely less on the influence of the operator“ (4).

How to achieve that?

There are three main products in our portfolio that support the packaging industry in improving the mentioned areas:

- CXF TOOLS for easy brand color communication

- The FLEX PACK system for the production of professional packaging proofs and prototypes

- X GAMUT for perfect spot colors, printed with an extended fixed ink set

- + our proofing paper and packaging substrates (MEDIA)

The biggest driver to improve color consistency

Besides the tools which help to communicate and exchange color easily through the entire supply chain with all partners and suppliers anywhere in the world (CXF TOOLS) and the system that allows you to produce color-accurate packaging proofs and prototypes easily and cost-effectively, X GAMUT gets a lot of attention in the industry. Why?

A lot of brand owners say that extended gamut printing is the biggest driver to improve color consistency, production efficiency, and environmental impacts.

They are sure, that this approach ensures color matching of packaging worldwide, irrespective of the geographical location of the printing facilities or different ability of the press operators. And they go even beyond that: „I am convinced that moving away from spot colors – where you have thousands of inks on a shop floor – will have a big impact on reducing cleaning time and on sustainability”, says Alvise Cavallari (Nestlé). And Cavallari continuous: “I believe that in future, ECG will become standard.” (5)

(1, 2, 3, 4, 5) cf. https://packagingeurope.com/digitalization-color-in-packaging-bright-future/

Benefits at a glance

- Easy & effective brand color organization and communication

- Error-reduction

- Dissociation of knowledge from individual color experts, simplification of processes

- Maximum productivity & efficiency

- Fast market entry

- Cost-effective packaging proofs and prototypes

- Direct-to-substrate proofing

- Accurate spot color reproduction with fixed ink set (ECG)

- Streamlined printing process

- Cost reduction & time savings

- Sustainable working

- Better prices, more competitive advantages

- Consistent color all over the world

Important links & contact

Do you have any questions? Please do not hesitate & get in touch with our team Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!