Achieve accurate spot colors and brilliant images - simply using CMYK+X

Special colors are especially eye-catching, but to work with them requires effort and expense. Extra inventory, higher prices, frequent color changes, and subsequent wash-up and press downtime all add up to reduced flexibility in job processing and significantly impact the whole production workflow.

As a result, the printing press is not used to the best of its potential, and productivity drops. That costs time and money.

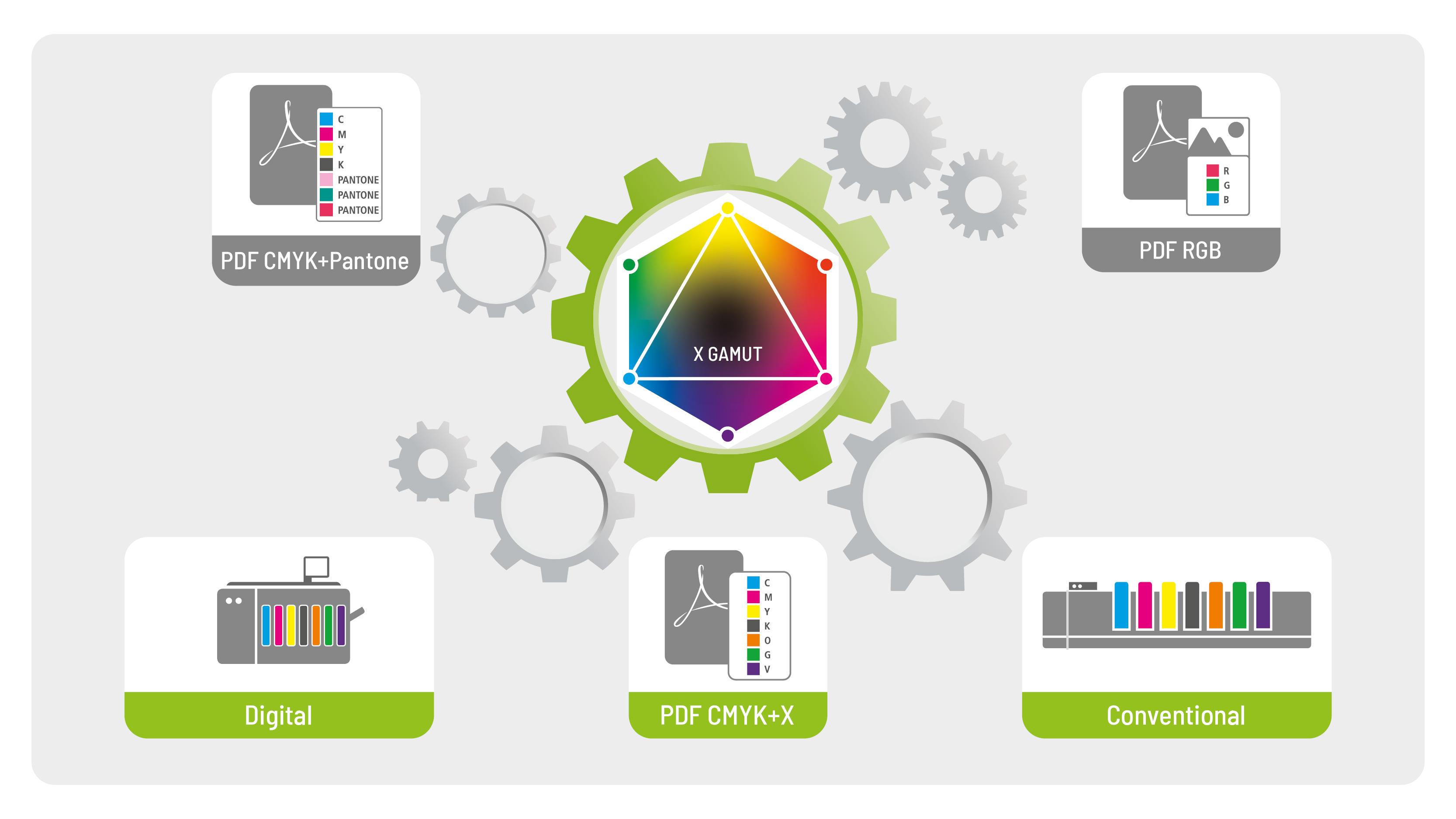

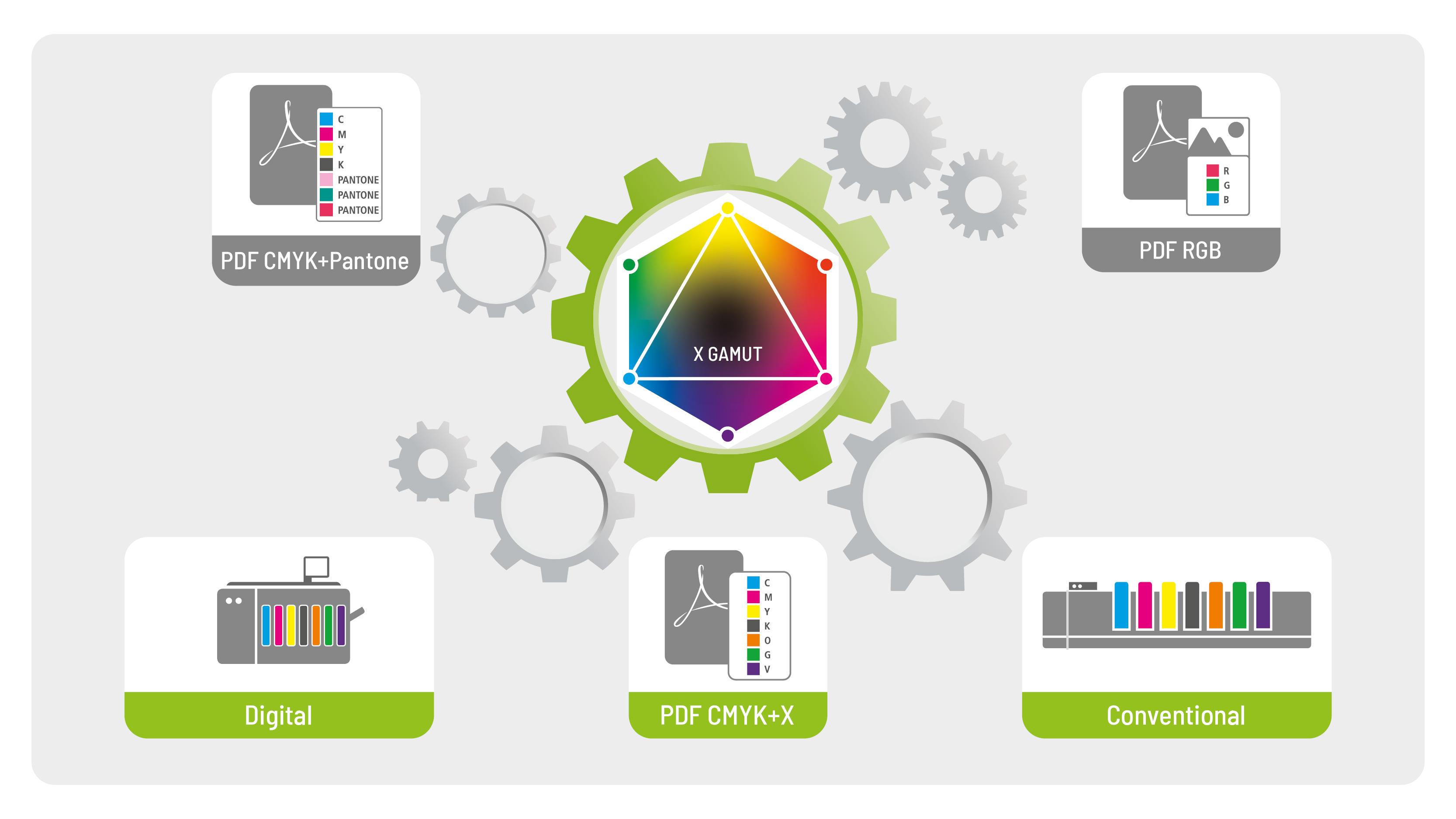

With X GAMUT, the fully automatic color management software for extended color printing on digital and conventional presses, spot colors can be accurately reproduced by using a standard fixed 7 or 8 color ink set (CMYK+X). Commonly, orange, green, and violet are added to CMYK.

That means you do not need to mess around with special ink mixes anymore. This considerably streamlines the production process since no press wash-ups, changeover times are necessary, greatly reducing ink inventory and waste. As a result, the software helps to reduce allover costs enormously - for printers and clients alike.

However, X GAMUT is not only ideally suited to reproduce spot and brand colors precisely. The perfect match of software features and intelligent workflow tools in X GAMUT enable printers to leverage the full gamut of the press and ink set so that images are brilliantly printed in all detail – without the need for special inks. This has made X GAMUT an important tool in the photo printing industry, too.

More details:

Spot color reproduction and correction

With X GAMUT you can reproduce spot and brand colors easily, accurately, and reliably with a fixed set of extended process colors. Typically, orange, green, and violet are used, but many other combinations are possible.

No matter which ink configuration you use, X GAMUT makes optimal use of your printer’s entire color gamut and reproduces spot and brand colors very precisely. The colors can also be optimized and verified.

Increasing image color saturation

Another important field where the strength of X GAMUT comes into play is the reproduction of RGB data. The color management software makes optimal use of the extended color gamut and delivers stunning print results with vivid, saturated colors – perfect for photo printing applications.

Separation and optimization of spot colors and images

The key to a perfect result is the intelligent separation of the measured color into the extended fixed set of process colors used in the printing process.

Spot and brand colors are replaced and reproduced without any spot inks while maintaining visual and colorimetric integrity. The conversion process optimizes the color data by reducing the number of separations to a minimum, thus minimizing the risk of moiré and clouding.

As a positive “side effect” this also reduces the total ink coverage, leading to shorter drying times and a leaner production process.

Creation of multi-color profiles

With X GAMUT you can easily create multi-channel profiles that can also be used in other applications.

Test chart generator

The built-in test chart generator allows you to create custom test charts for your printing presses. These test charts are essential for the CMYK+X color conversion process to characterize the color space of your printing system.

X GAMUT supports all commonly used measurement devices, including the latest models from X-Rite, Konica Minolta, or Barbieri.

Management of spot color libraries

The X GAMUT software includes standard spot color libraries from Pantone and HKS. In addition to that, you can also create your own libraries and import and edit color data via CxF. There is also a direct interface to the

CXF CLOUD to communicate all colors with all of their spectral properties easily and quickly all over the world.

Central control

Trust is good, control is better: With our easy-to-use software

CERTIFIED users are able to quickly verify prints for color accuracy and to store and evaluate all kinds of data from different devices in a central location. This gives every authorized user a detailed overview at any time.

Key features

| Accurate spot color reproduction with an extended standard ink set (CMYK+X) |

| Photo printing with vivid, high saturated colors |

| Automatic separation of PDF files with spot colors as well as RGB data into multi-channel data |

| Generation of multi-channel profiles and custom test charts |

| Interface to standard spot color libraries (e.g. Pantone) |

| Create and edit your own color libraries |

| Easy and quick creation, processing, and exchange of CxF data and spectral measurement data |

| Simple handling and perfect results thanks to wizard-based user interface |

| Fully automated processes thanks to intelligent workflow tools |

| Immediate process and quality control with CERTIFIED |

| Intelligent automation: Route jobs automatically to the best press for the most accurate color reproduction |