7 reasons why color management software and professional proofing solutions push the digital transformation of printing companies

This article briefly illuminates the potential color management and proofing technology has for companies of the graphic industry to push their digital transformation and improve processes.

Digitalization, automation, and sustainability are keywords these days. The corona crisis and the shutdowns are powerful drivers of change processes in SMEs as well as huge global companies. Branch surveys show what the biggest challenges for printers and packaging printers are and in which areas many of them focus to emerge from the crisis stronger than before.

Digitalization, automation, and sustainability are keywords these days. The corona crisis and the shutdowns are powerful drivers of change processes in SMEs as well as huge global companies. Branch surveys show what the biggest challenges for printers and packaging printers are and in which areas many of them focus to emerge from the crisis stronger than before.

This article briefly illuminates the potential color management and proofing technology has for companies of the graphic industry to push their digital transformation and improve processes.

7 reasons at a glance

Important links & contact

Do you have any questions? Please do not hesitate & get in touch with our team Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

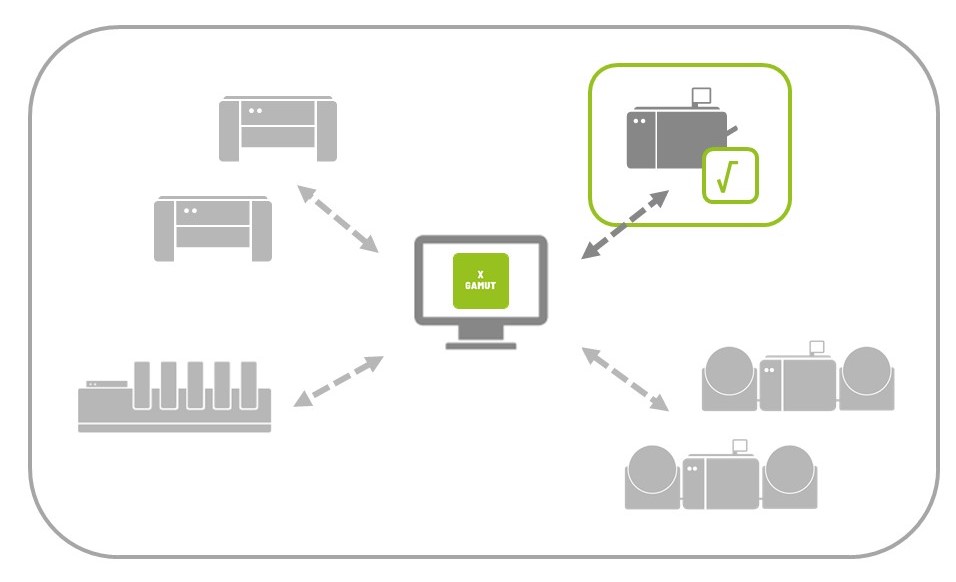

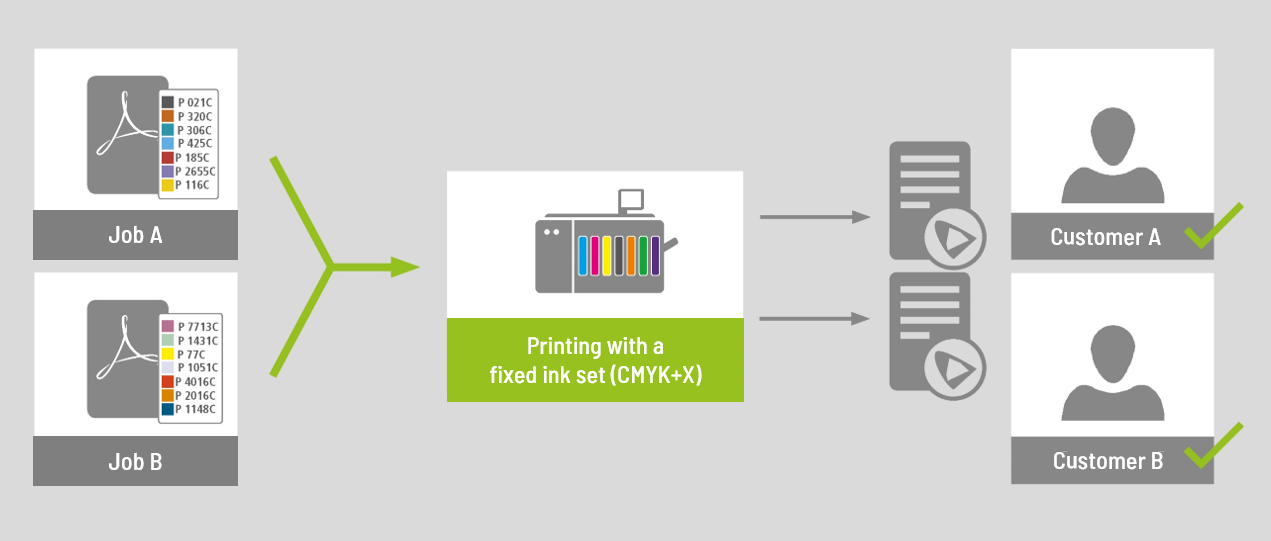

Another interesting fact is that intelligent color management technology has the potential to support you with clear facts which of the printing presses in your production hall (locally or globally) fits the best for the jobs.

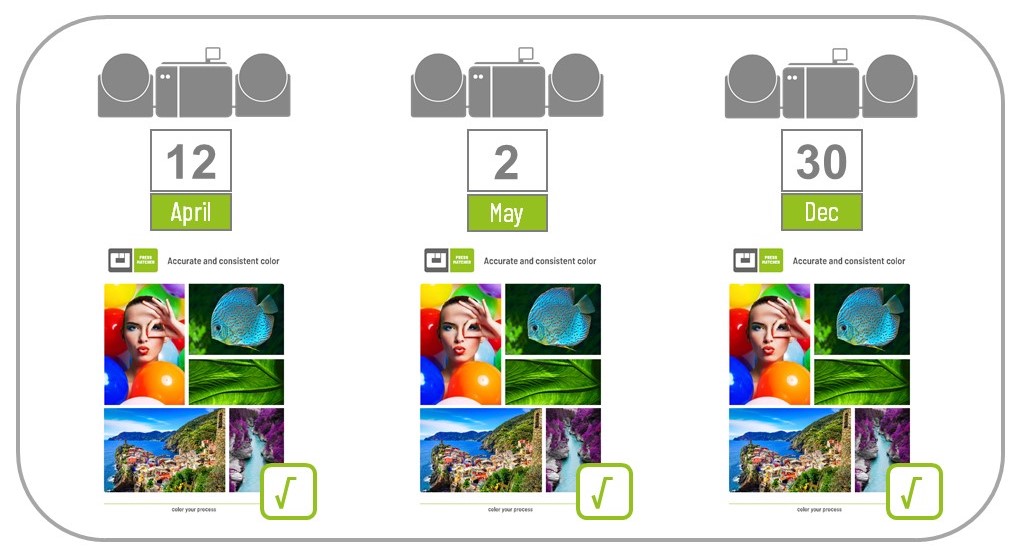

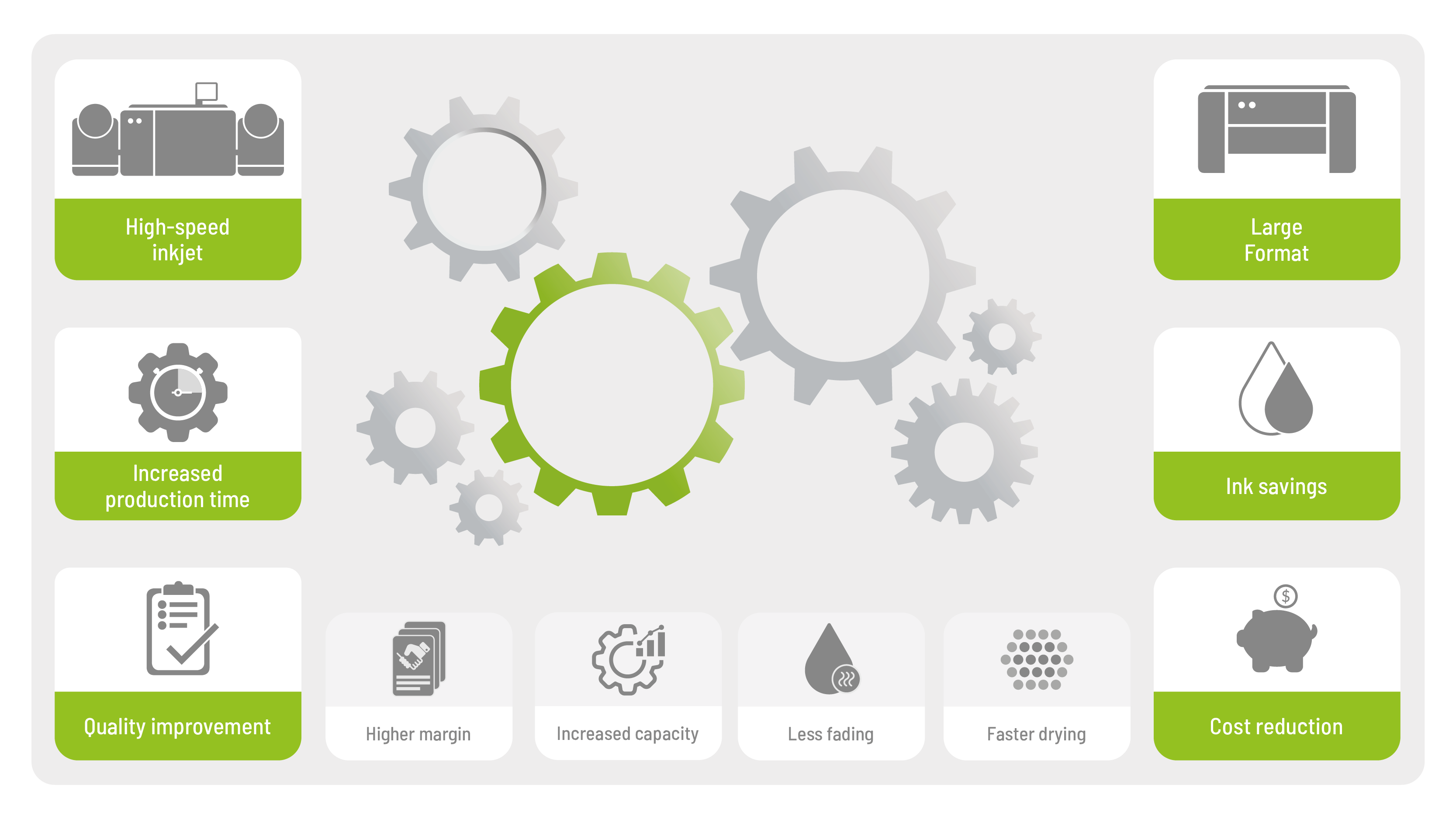

Another interesting fact is that intelligent color management technology has the potential to support you with clear facts which of the printing presses in your production hall (locally or globally) fits the best for the jobs. Of course, it´s not new that customer complaints and maculature are not good for your business, but besides the economic dimension, nowadays the ecological perspective gains more and more attention.

Of course, it´s not new that customer complaints and maculature are not good for your business, but besides the economic dimension, nowadays the ecological perspective gains more and more attention. Color management software which has been specially developed for print production will help you to achieve a much more efficient printing process, it will avoid unnecessary change-over times or downtimes in our production hall.

Color management software which has been specially developed for print production will help you to achieve a much more efficient printing process, it will avoid unnecessary change-over times or downtimes in our production hall.

In general, professional color management and proofing software should be simple to use and work intuitively although it is really “heavy stuff”.

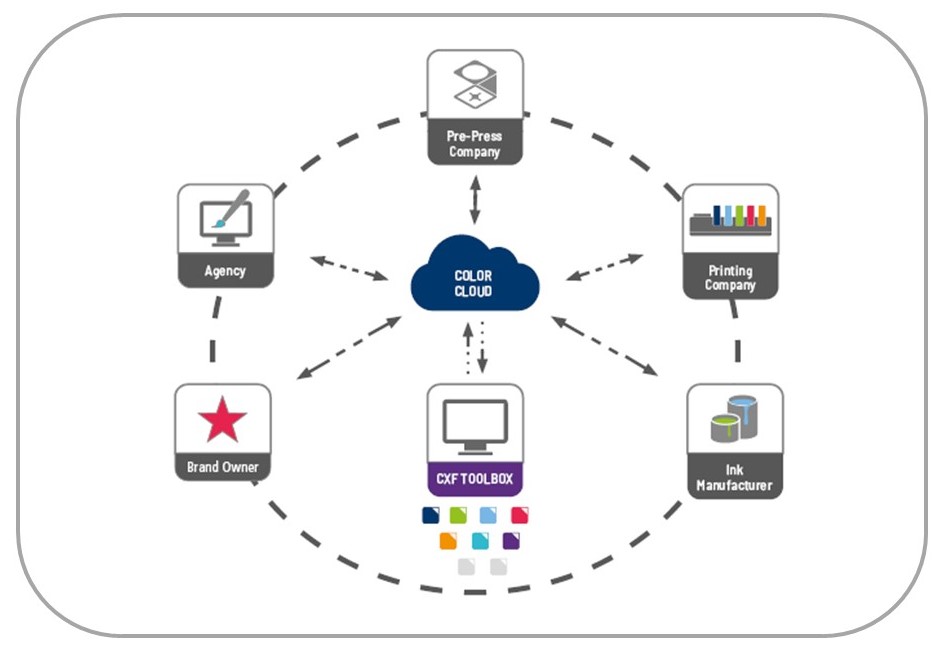

In general, professional color management and proofing software should be simple to use and work intuitively although it is really “heavy stuff”. Every day, many companies of the graphic arts industry still face difficulties due to the communication of incomplete or misleading color information. This still causes many challenges, additional print runs, and costs recourses and money.

Every day, many companies of the graphic arts industry still face difficulties due to the communication of incomplete or misleading color information. This still causes many challenges, additional print runs, and costs recourses and money.