Simple and effective quality control for proofs, press sheets, digital and conventional print systems

Simple and effective quality control is essential for delivering optimal print results and consistent quality. Ideally, the system informs the user, whenever a device or process deviates from a set standard and requires optimization or user intervention.

CERTIFIED enables you to easily measure and evaluate color wedges on any proof or press sheet. Color wedges for commonly used standards such as SWOP, GRACoL, 3DAP, FOGRA are included and custom color wedges can be added easily.

To verify spot colors, users can create their own color set by selecting spot colors from a library or entering its LAB values. CERTIFIED measurement results can be printed on a self-adhesive label to be put on the proof or as a detailed report.

The intelligent tool provides company-wide overviews, detailed reports, and trend analyses - all with just a few clicks. Clear facts help you to avoid any discussions about color problems.

The web-based software can be easily integrated into existing infrastructures and workflows. It is extremely effective and flexible and at the same time easy to use thanks to its intuitive wizard-based user interface.

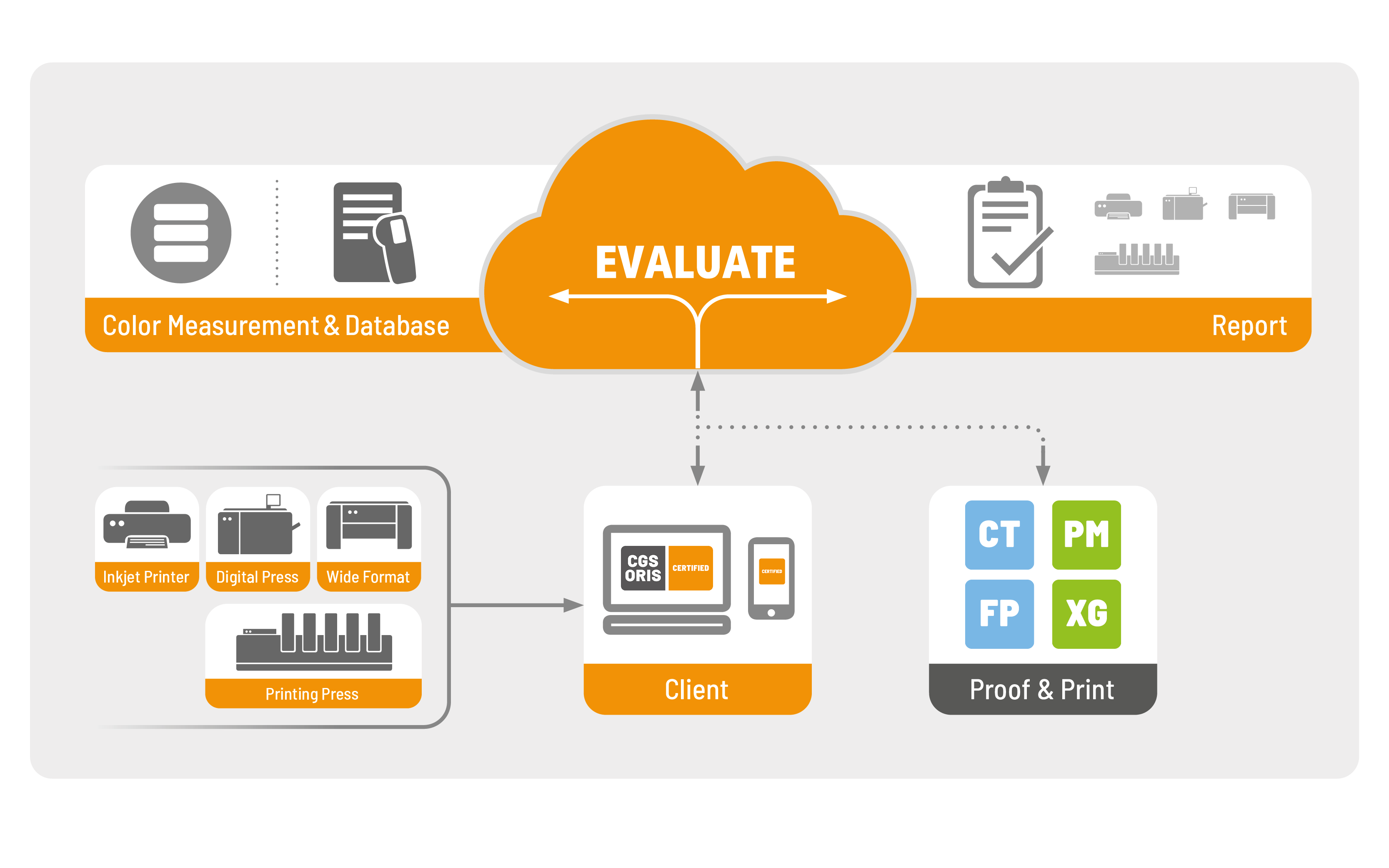

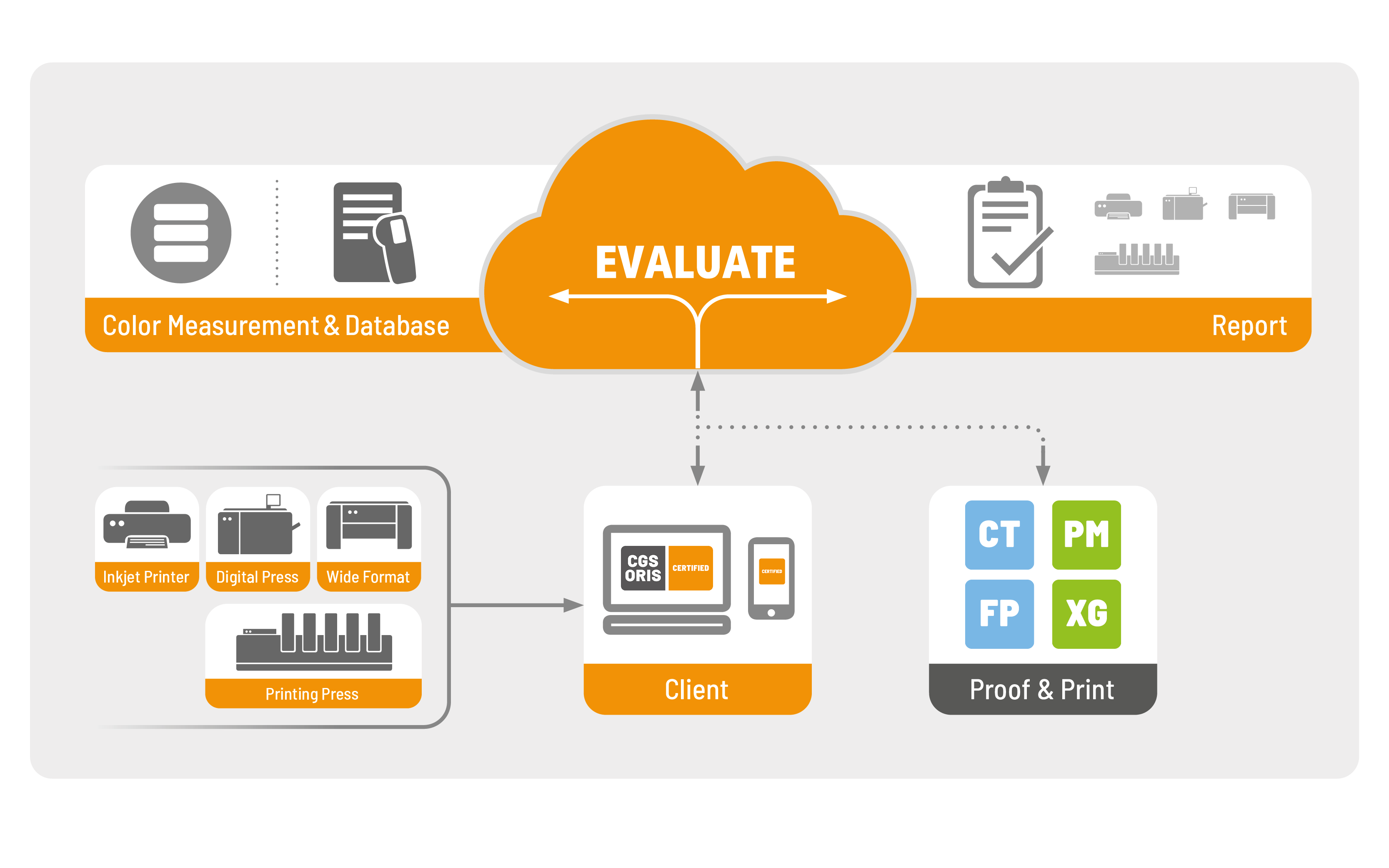

Optionally, it connects to the EVALUATE web server, to which the measurement results of all monitored devices are automatically saved. The data can be accessed and evaluated from anywhere in the world via a web browser.

More details:

Real-time

- Dashboard for viewing current print performance across multiple sites.

- Immediate notification of errors, giving you more time to fix problems.

Centralized information

- Access EVALUATE from anywhere via an internet connection.

- Overview of the entire production chain from proof to print.

- Monitor device performance live, no matter where you are.

- Get quality control over remote/off-site proofing systems.

Business intelligence

- Detect consumables variation.

- Evaluate device performance and error rates.

- Generate reports highlighting which variables in your process are contributing to your rework and errors.

Profitability

- Common platform and language to communicate problems and fixes across multiple departments.

- Key to job consistency on different presses, overtime, or even at different sites.

- Monitor supplier’s raw material quality.

- Use CERTIFIED to create job quality reports as a marketing tool for prospective and current customers.

Green and lean

- Reduce variation in quality by identifying problems and root causes. Understanding raw materials variation is critical to efficient production.

- Reduces waste by identifying problems at their source. Identify incorrect proofs and plates before they enter the press room.

- By using CERTIFIED for color matching to ISO or other standards as well as for plate performance monitoring, you can ensure that colors are accurate before proofs are sent, eliminating the

guesswork from remote proofing and reducing shipping costs.

Key features

| Easy to use & effective quality control system |

| Web-based monitoring of all devices and processes |

| Overview of all print quality parameters from anywhere in the world |

| Dashboard of enterprise-wide performance |

| Color wedges for all common printing standards |

| Tool to create custom color wedges, target values, and tolerances |

| Measure LAB, color density, or dot coverage values |

| Media-relative color evaluation |

| Significant evaluation in real-time |

| Time, material, and cost savings |

| Simple handling and perfect results thanks to the wizard-based user interface |

| Easy integration into existing workflows, infrastructures, and other CGS ORIS applications |

Do you have any questions?

Please don´t hesitate and get in touch:

Europe, Asia, Africa, Australia/NZ:

CGS Publishing Technologies

International GmbH

This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel.: +49 6182 9626 0

Fax +49 6182 9626 99

North America & South America:

CGS Publishing Technologies

International LLC

This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel.: +1 612 870 0061

Fax +1 612 870 0063