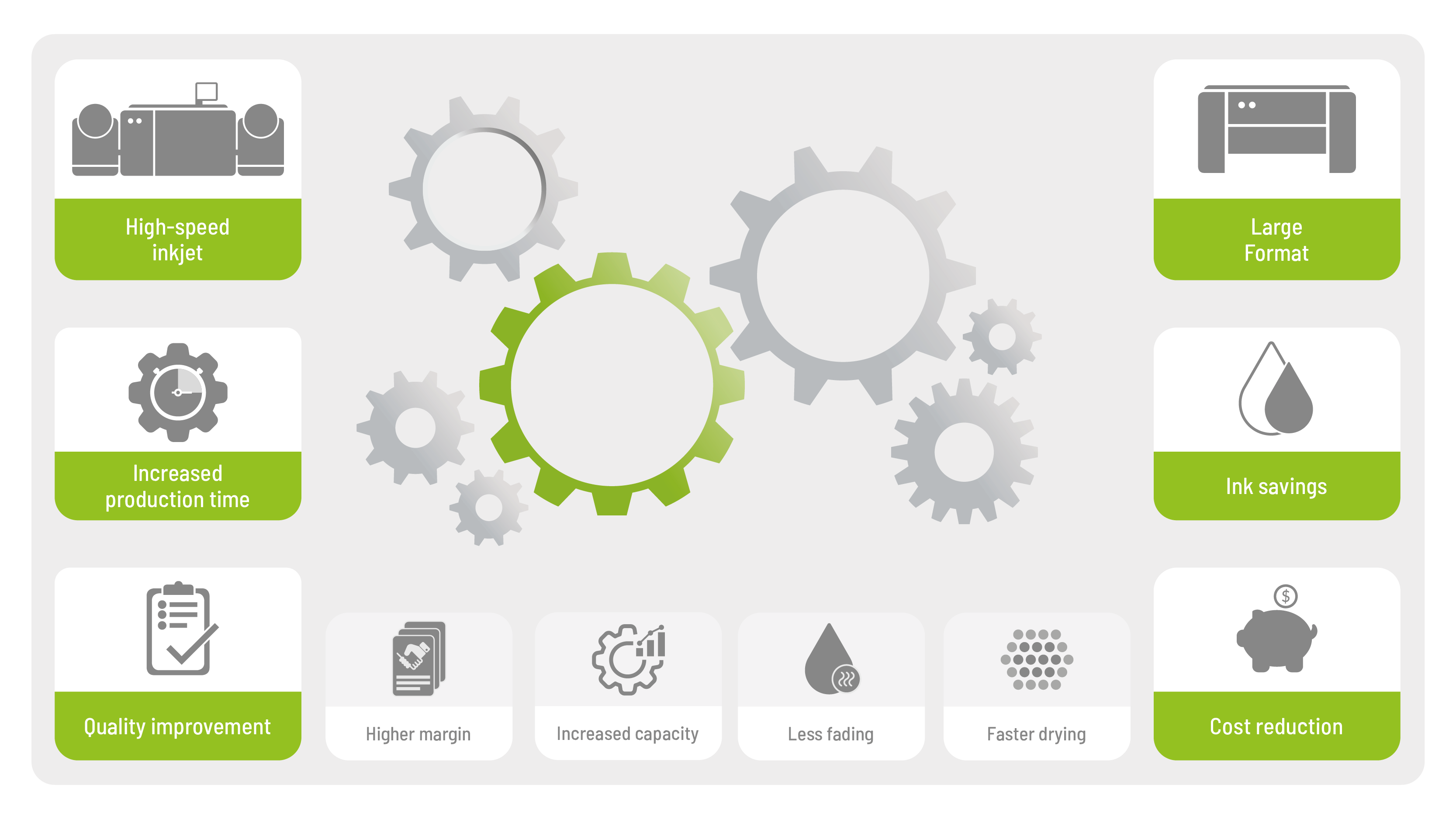

Ink Saving and Quality Improvement

Thursday, 11 February 2021The INK SAVER module of PRESS MATCHER has been developed to not only create substantial ink savings on press but to also optimize the entire production process.

With an ink reduction of usually 20 percent or even more, not only a significant cost reduction is achieved, but also a substantial increase in print quality.

An overall lower ink coverage optimizes print contrast and enhances visible details. Spot and brand colors are also displayed more precisely.

Printing with less ink automatically leads to faster drying times and significantly increases your production speed. Print capacity that can be used for new customer orders. As a result, you can process more print jobs from your customers at the same time!

Besides that, negative effects from environmental factors are also minimized. Banners and signboards are less susceptible to fading and abrasion.

Printing more jobs means more profit; usually, INK SAVER pays for itself within less than a year.

More details:

Do you have any questions?

Please don´t hesitate and get in touch:

Europe, Asia, Africa, Australia/NZ:

CGS ORIS GmbH

This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel.: +49 6182 9626 0

Fax +49 6182 9626 99

North America & South America:

CGS Publishing Technologies

International LLC

This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel.: +1 612 870 0061

Fax +1 612 870 0063

Stiefel Digitalprint & Eurocart GmbH, Lenting

Friday, 09 August 2019What’s most important in this solution is very clear to us, and that’s the quality improvement that we can achieve with it.

Case Study: Stiefel Digitalprint & Eurocart GmbH

Friday, 09 August 2019Quality Improvement with INK SAVER

By reducing ink, quality improvement is not possible, right? At first glance, most people will agree with this correlation. It’s unanimously believed that if you reduce the amount of ink the quality of the print will suffer. However, the opposite is true if you use the right tools as demonstrated here by the international STIEFEL Group.

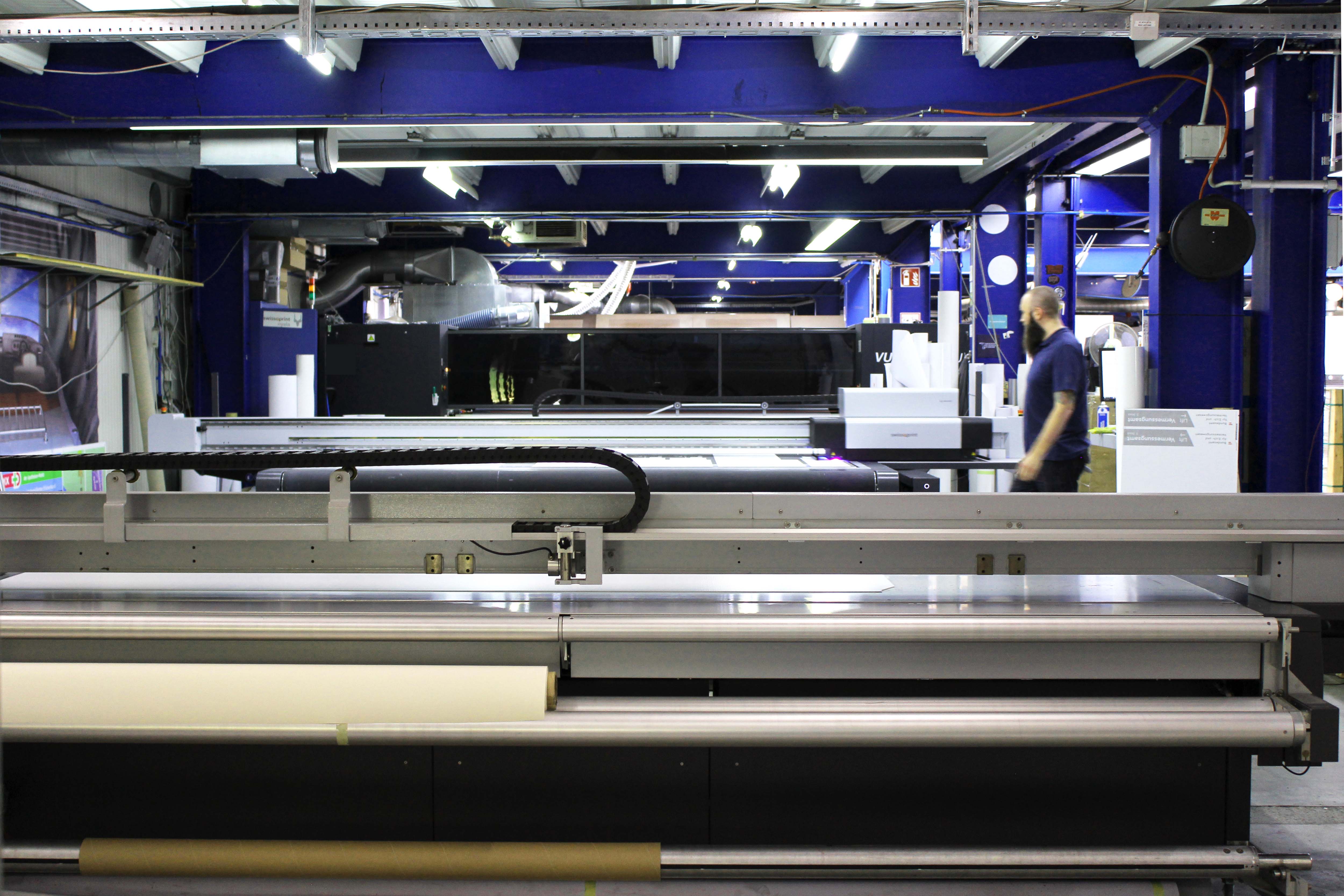

Situated in Lenting, close to Ingolstadt, the company has 14 printing machines, 2 high-frequency welding towers, 4 guillotines and 3 laminators in their 5500m2 production hall.

Every day thousands of square meters of printed materials from giant fabric prints for flags, wall coverings, canopies and tablecloths, complex display banners and building wraps to foil printing for expo booths and vehicle wraps are produced. Direct printing to board and fleece wallpaper with imposing designs complete the STIEFEL portfolio.

This Upper Bavarian company also provides post-processing, delivery and assembly of the final product on site. Managing Director Bernhard Stiefel’s first priority is providing his customers with the best quality possible. Software from CGS gives him exactly that.

Just over a year ago, STIEFEL installed PRESS MATCHER with the INK SAVER module. “What’s most important in this solution is very clear to us, and that’s the quality improvement that we can achieve with it”, Bernhard Stiefel comments. “Printed results show considerably improved sharpness, they are noticeably more brilliant and edges are clearly defined” he said with satisfaction.

At first, he didn’t expect such incredible results. “We had already tried other ink-saving solutions, but none even came close to what we desired and this is why we were not convinced it was even possible. I was very positively surprised, because the results printed with ORIS Ink Saver even overachieved what CGS ORIS´ business partner, DRX Pack, had reported the software would deliver”, summarized Stiefel.

What’s most important in this solution is very clear to us, and that’s the quality improvement that we can achieve with it.

As well as the increase in quality, ink-saving was also outstanding. On average, the company is saving around 20 % in ink. For example on the Canon Colorado that‘s 22% in saved ink costs. On certain printing machines the ink saving was even greater.

Ink savings can depend on factors such as image design, printing substrate and the machine itself. STIEFEL has a wide range of equipment from DURST, HP, VUTek, Canon and SwissQPrint. “We save most on the foil machines where we see up to 35%”, according to Stiefel.

Over and above the quality and cost-saving benefits the Managing Director praised the ease of integration of the software with his existing workflow.

As well as quality improvement and less ink usage, the INK SAVER module brings other unexpected benefits along with it. Because there is less ink on the substrate, drying time is reduced so that the production process can be speed up and the printer freed up for additional customer projects.

The origins of STIEFEL lie in the printing of maps. Bernhard Stiefel’s father, Heinrich, founded the company in 1982 with the idea of outfitting every school classroom with geography maps; in those days mostly by offset printing. “In the 90’s we started to use digital printing more and more, particularly as the many changes in European country borders meant constant map updates and that would not be economical on offset”, explains Bernhard Stiefel, who has led the company with his father since 1990.

So finally, in 2003, STIEFEL Digitalprint GmbH was formed alongside the existing STIEFEL Eurocart GmbH. Maps in various forms are still produced today through the major part of the business is advertising and display material of every kind and size. The Group has around 100 employees, mostly in Lenting in beautiful Oberbayern.

(Photo Credit: CGS)

Ink/Toner Saving

Monday, 23 November 2015In today's printing industry it is important to reduce costs while maintaining a high level of quality. This can be achieved easily using PRESS MATCHER together with INK SAVER Premium.

The INK SAVER option significantly reduces the CMY components for all printed elements, resulting in less consumption of expensive CMY ink or toner.

Using sophisticated UCR and GCR algorithms, INK SAVER also optimizes the black separation, which improves color quality in digital and conventional printing. Reduced make-ready time and waste and faster ink drying times are additional benefits. Get more information.

Case Studies

Read our case studies for more information.