Canon imagePROGRAF PRO Series

|

Printer model |

Max. media width |

License |

ScreenDot proof |

|---|---|---|---|

|

PRO-1000, 500 |

420 x 594 mm (A2) |

Small |

– |

|

PRO-2000, 520 |

610 mm (24”) |

Medium |

– |

| PRO-2100, 521 | 610 mm (24”) | Medium | – |

|

PRO-4000, 540 |

1118 mm (44”) |

Large |

– |

|

PRO-4000S, 540S |

1118 mm (44”) |

Large |

Yes |

| PRO-4100, 541 | 1118 mm (44”) | Large | - |

| PRO-4100S, 541S | 1118 mm (44”) | Large | - |

| PRO-6000, 560 | 1524 mm (60”) | Large | – |

| PRO-6100, 561 | 1524 mm (60”) | Large | - |

|

PRO-6000S, 560S |

1524 mm (60”) |

Large |

Yes |

| PRO-6100S, 561S | 1524 mm (60”) | Large | - |

Canon imagePROGRAF GP Serie

|

Printer model |

Max. media width |

License |

ScreenDot proof |

|---|---|---|---|

|

GP-2000, GP-520 |

610 mm (24”) |

Medium |

– |

|

GP-4000, GP-540 |

1118 mm (44”) |

Large |

– |

Canon imagePROGRAF iPF Series

|

Printer model |

Max. media width |

License |

ScreenDot proof |

|---|---|---|---|

|

iPF9400S, 9410S |

1524 mm (60") |

Large |

Yes |

|

iPF9400, 9410 |

Yes 1 |

||

|

iPF9100 |

|||

|

iPF9000S |

|||

|

iPF9000 |

|||

|

iPF8400S, 8410S |

1118 mm (44") |

Large |

Yes |

|

iPF8400, 8410 |

Yes 1 |

||

|

iPF8300S, 8310S |

|||

|

iPF8300, 8310 |

1118 mm (44") |

Large |

|

|

iPF8100 |

|||

|

iPF8000S |

|||

|

iPF8000 |

|||

|

iPF6400S, 6410S |

610 mm (24") |

Medium |

Yes |

|

iPF6450, 6460 |

Yes 1 |

||

|

iPF6400, 6410 |

|||

|

iPF6300S |

610 mm (24") |

Medium |

Yes 1 |

|

iPF6350, 6300, 6310 |

|||

|

iPF6200 |

|||

|

iPF6100 |

|||

|

iPF6000S |

|||

|

iPF5100 |

432 mm (17") |

Small |

|

|

iPF5000 |

|||

|

iPF810, 820 |

1118 mm (44") |

Large |

– |

|

iPF750, 755, 760, 765 |

914 mm (36") |

Large |

– |

|

iPF650, 655 |

610 mm (24") |

Medium |

|

|

iPF700, 720, 710 |

914 mm (36") |

Large |

– |

|

iPF600, 605, 610 |

610 mm (24") |

Medium |

– |

|

iPF500, 510 |

432 mm (17") |

Small |

– |

Canon imagePROGRAF W Series

|

Printer model |

Max. media width |

License |

ScreenDot proof |

|---|---|---|---|

|

W8400PG |

1118 mm (44") |

Large |

Yes |

|

W8400 |

– |

||

|

W6400PG |

610 mm (24") |

Medium |

Yes |

|

W6400 |

– |

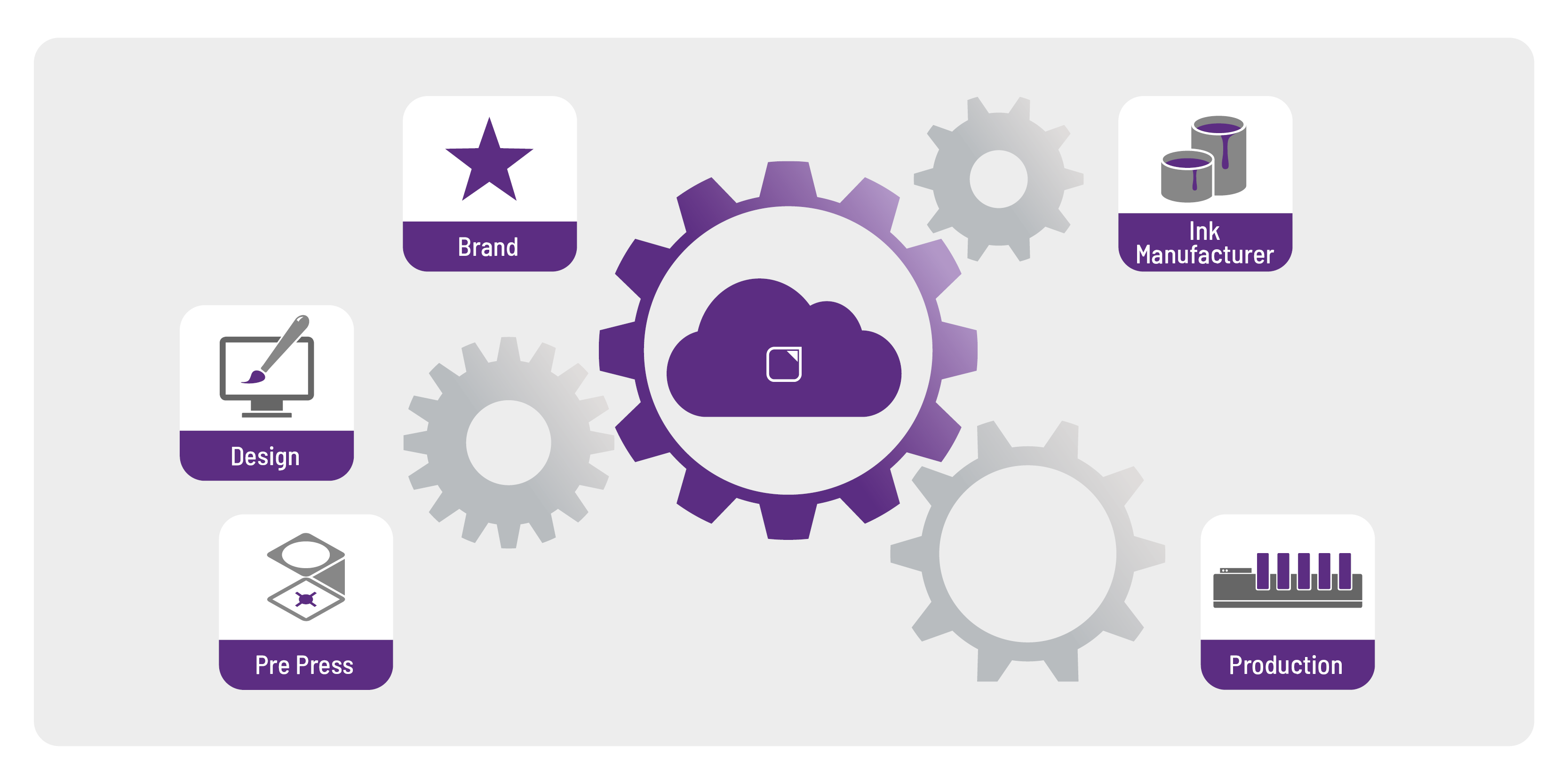

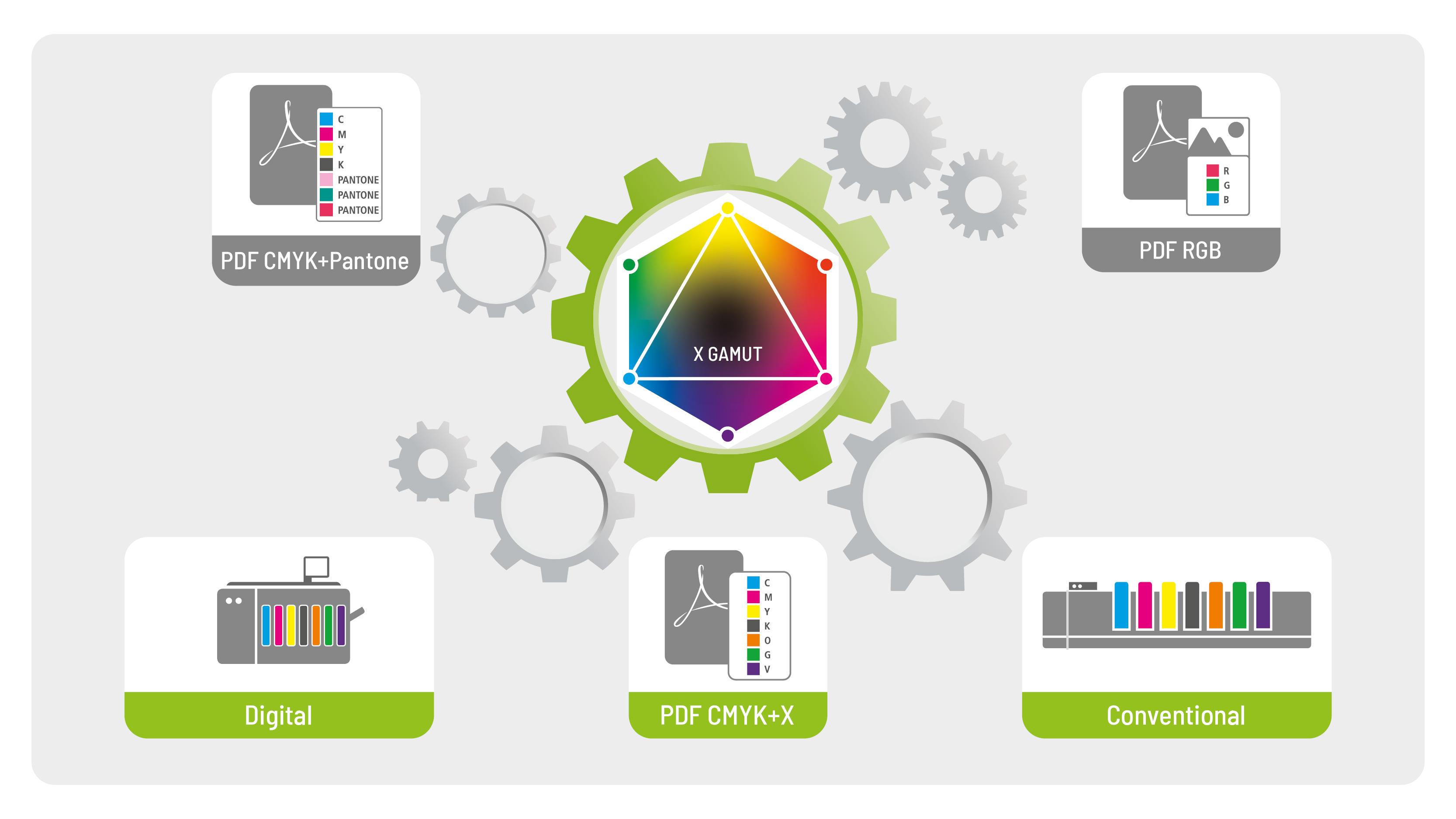

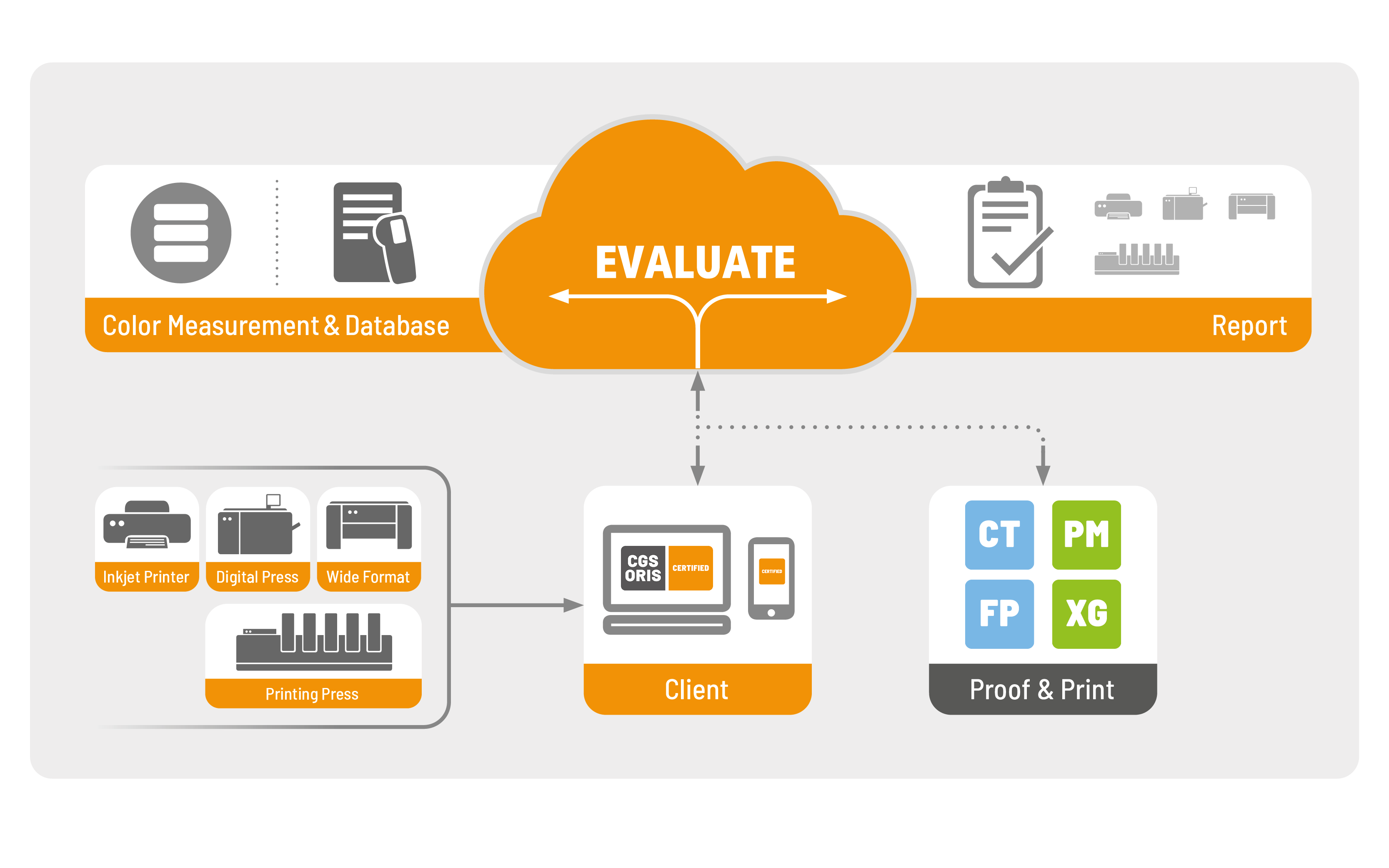

From initial design to the digitally or conventionally printed product, color communication always needs to be reliable, effective, and easy. The ability to organize brand color information with all of its print-related properties is the essential basis for that.

From initial design to the digitally or conventionally printed product, color communication always needs to be reliable, effective, and easy. The ability to organize brand color information with all of its print-related properties is the essential basis for that.